Finland

2019 – 2021

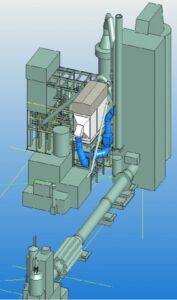

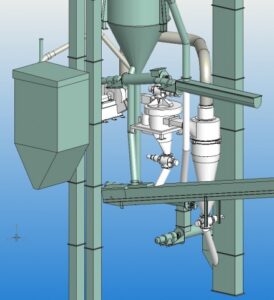

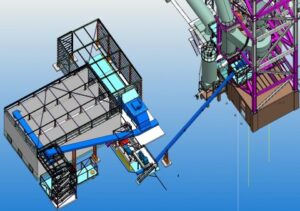

New slag grinding circuit

Preliminary process- and layout design, main equipment inquiries, tender comparisons and negotiations, project cost estimate and time schedule, electrical planning and automation including process control description, testing and commissioning.

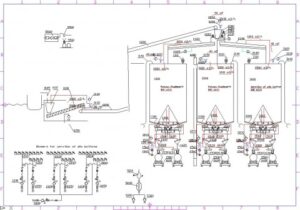

Slag meal reception, storing and handling

Project engineering, design and supervisionfor renovation and upgrading of storage silos, discharge, re-conveying and feeding system to mills.

Cement plant: kiln filter and by-pass dust discharge and conveying

Project engineering, layout design and supervision.

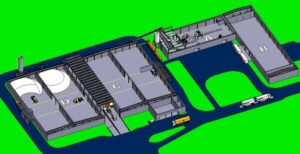

A quarry: Preliminary design of a cement and slag meal storage including dosing system.

Cement terminals

Several electrical and automation related planning and know how tasks.

2018

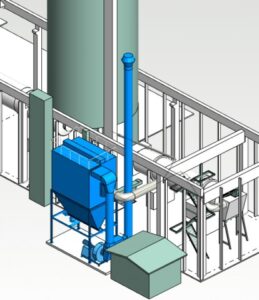

Conversion of kiln ESP to bag house filter

Layout design, main equipment tender documents, comparisons and participation in the procurement procedure

Planning of slag storage, reception and batching equipment and readying inquiry documents.

Electrical planning, testing and commissioning for new slag mill main motor and starter.

Electrical planning and process control description for slag terminal ship loading devices.

Electrical planning and process control description, acquisition queries and comparisons for cement terminal

Various minor electrical improvements and documentation for lime plant

2017

Slag grinder circuit separator improvement project

Layout design, main equipment tender documents, comparisons and participation in the procurement procedure.

Cement terminal silo drain rate improvement project

Preliminary layout design, electrical- and process control system planning.

Electrical planning for new cement terminal car loading equipment

2016

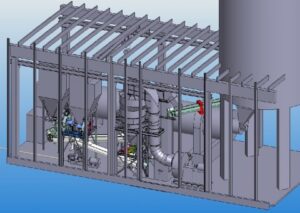

New Alternative Fuel project at a cement plant

Including logistics, receiving, conveying and feeding to grinding unit and conveying from grinding unit to the existing feeding silo

New exhaust gas cleaning system for a drum dryer

Preliminary layout design, main equipment tender documents, comparisons and participation in the procurement procedure, electrical- and process control system planning and project engineering, participation and testing and starting up

Pre-study for installing a new high efficiency separator at an existing closed slag grinding circuit

Renewal of the electrical- and process control system at a slag meal terminal

Cement terminals – various minor electrical- and process control improvement tasks

Lime kiln new exhaust gas cleaning system

Electrical- and process control planning and programming at the interface areas of the main kiln control system

Layout design for a new high efficiency separator at a lime plant

Lime plant – various minor electrical- and process control improvement tasks

2015

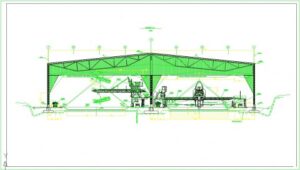

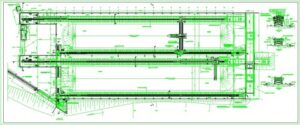

New storage halls at a port: Electrification and illumination design

Boiler plant: soft ware application engineering modifications at the border line of the new and existing process control system

Renewing of the automation system at a cement terminal

Fly ash (large) conveying system delivery to Russia

Project engineering of the electrification and process control system as a sub supplier for a Finnish equipment supplier

Participation in the testing, commissioning and start up during summer and autumn 2015

Various electrical planning and soft ware application engineering tasks at a lime plant

2014

Receiving system for pneumatic ship unloading at two cement terminals

Electrical & automation planning including commissioning

Cement terminals and lime plant

Various small electrical and process control improvements

Large fly ash conveying system delivery to Russia

Project engineering of the electrification and control as a sub consultant to a Finnish equipment supplier as well as

Electrical planning

Programming of individual machines internal control system

Finnish supplier of bulk handling systems

Supporting the quotation phase with pre-engineering of the electrical and automation system as a sub consultant

Paper Mill

Varous minor mechanical design tasks mainly related to work safety improvements

2013

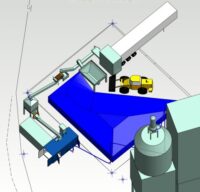

Terminal for receiving, storing and packing of different granular and powdery bulk material. Packing into big bags, small bags and pounches.

Planning of the technical concept, flow sheet and layout (2 & 3D), definition of equipment, equipment inquiries and equipment cost estimate. Electrical and automation concept including cost estimate.

Cement silo. New automaticvally controlled discharge outlets.

Technical concept including including Pi diagram, layout, functional description and cost estimate.

Fly ash silo. Receiving, discharge and re-conveying.

Electrical and automation project engineering, electrical planning, software planning including programming and start up.

Lime slaking syatem – replacing of the outdated process control system

Electrical planning, survey of the existing system for software planning, programming and installation of the new system.

Bulk loading of limestone – dedusting system

Electrical and softweare planning including programming and delivering of the control system.

Cement silo terminal – renewing of the control system

Project engineering task.

Fly ash conveying system delivery to Russia

Basic engineering of the electrical and automation part for a Finnish equipment system supplier.

2010 – 2012

Electrification, automation and process control

- Upgrading of existing cement terminals

- Process control system improvements on a lime plant

- For equipment suppliers (pneumatic conveying and crushing)

Tasks: electric planning, process control descriptions, programming (Siemens, ABB and Allen Bradley), testing and commissioning.

Supply of small electrical cabinets and process logic control systems as well as complete deliveries tested and commissioned.

2011

Cement plant: Various pre engineering plans at limestone handling and cement grinding departments.

2005 – 2007

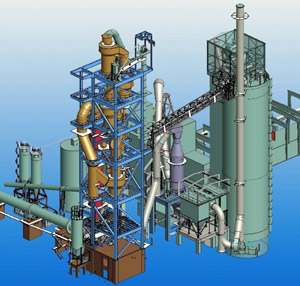

New clinker kiln system (1800 t/d)

- Participation from preplaning to implementation

- Main layout design

- Design coordination

- Cost estimation

- Time planning

- Electrification, instrumentation and process control

- Project management, coordination and engineering

- Interface project (from preplanning to implementation)

- New fuel (fine coal) conveying and storing system, dosing and conveying to kiln main burner and precalciner

- Kiln freed system

- Re-location of existing MBM storage and feeding system

- Clinker conveying to the existing storage hall including reject silo

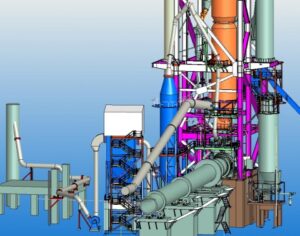

2008 – 2009 Kiln ”by pass” system

- Project coordination and layout desig

2008 – 2009 Alternative fuel (RDF) storing and handling system Refuse-derived fuel (RDF) or solid recovered fuel/ specified recovered fuel is a fuel produced by shredding and dehydrating municipal solid waste in a converter or steam pressure treating in an autoclave. RDF consists largely of organic components of municipal waste such as plastics and biodegradable waste

- Project coordination and layout design

Cement terminal 3 x 9000 t (1998-1999)

- Over all project coordination and engineering from preplanning to implementation (equipment, electrification and automation)

- Separate civil design and consultant

Cement terminal preplanning (3×7000 t) (2004-2006-2008)

- Separate civil design and consultant

Limestone homogenization (2001- 2002)

- Main machinery moved as redundand from another plant

- Over all project coordination and engineering from preplanning to implementation (equipment, electrification and automation)

- Separate civil design and consultant

More in the Finnish cement industry

- Handling of kiln dust (2003-2004)

- Alternative fuel (2002-2003)

- New main burners for three (3) kilns (2001-2002)

- Cement storage silo modernizations

- New bulk loading stations (truck and train)

- Cement grinding: many conversions from open to closed circuit grinding

- Many different de-dusting system projects

Slag grinding station

- New process control system (2007- 2008)

- Several small projects like de-dusting (2003-2007)

- Storing and ship loading of ground slag (1997)

New lime shaft-kiln (1997-1998)

- Layout and general arrangement design

- Interface project engineering and coordination

- Electrification, instrumentation and process control system

- Project engineering and coordination

Fly ash separation, handling, storing and truck loading (2003)

- Preplanning and feasibility study project

Leca (light expanded clay) line (1988)

- Modernisation pre-plan of the whole kiln line